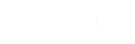

Precision-Crafted Spare Parts for Moulding Machines

At RainbowShoes, we specialize in the manufacturing of high-quality spare parts for footwear moulding machines. With a strong commitment to performance, reliability, and innovation, we cater to the evolving needs of footwear production units across India and beyond. Our spare parts are designed with precision engineering, ensuring compatibility with a wide range of moulding equipment used in sole, heel, and full shoe production. Backed by industry experience and modern manufacturing practices, RainbowShoes is the trusted name for durable, efficient, and ready-to-fit moulding machine components.

Key Benefits of Our Spare Parts

Our spare parts are designed to deliver precision, durability, and efficiency. Each component is crafted to ensure a perfect fit, reduce machine downtime, and extend the life of your moulding equipment. With high-grade materials and consistent quality checks, RainbowShoes parts help maintain smooth production, lower maintenance costs, and improve overall machine performance.

- Engineered for flawless compatibility with all major moulding systems

- Built using high-grade materials to withstand rigorous production cycles

- Extend machine life and reduce downtime with reliable, long-lasting components

- Standardized parts ensure fast turnaround and minimal production loss

- Tailored spare parts available for niche requirements or legacy systems

Industries We Serve

These industries rely on moulding machine parts to ensure consistent shape, durability, and speed in mass footwear production, minimizing errors and ensuring product uniformity.

Footwear Manufacturing Units

For consistent sole and upper moulding operations

Our spare parts support seamless production of soles, uppers, and complete footwear units.

Ensures consistent output and reduces machine breakdowns in high-volume environments.

Furniture Manufacturing Industry

To support high-precision moulding cycles

Involves moulded plastic parts for chairs, armrests, and fittings. Durable spares help in handling large and repetitive production tasks.

Automotive Industry

Uses moulded parts for dashboards, trims, and interior fittings, demanding high-durability machine components.

Utilizes moulded parts for interiors, panels, grips, and sealing components.

Demands robust, wear-resistant parts for high-volume moulding machines.

Electrical & Electronics Industry

Requires precision-moulded parts like switchgear, housings, and connectors for safe performance.

Moulds plastic components such as switches, sockets, casings, and wiring parts.

Precision spares are essential to avoid downtime and maintain tight tolerances.

Medical Equipment Industry

Depends on accurate, sterile plastic moulded components for critical healthcare applications.

Requires high-quality moulding for sterile, precise plastic components.

Spare parts must meet high standards for hygiene and reliability.

Household Product Industry

Produces items like storage bins, containers, and furniture parts using high-efficiency moulding machines.

Manufactures daily-use plastic items like buckets, tubs, bins, and storage boxes.

Relies on durable spare parts for high-output and long-running machines.

FAQ's

We manufacture a wide range of spare parts for footwear moulding machines, including clamps, heaters, toggle units, hydraulic components, and custom-fit parts for various models.

Yes, our parts are designed to be compatible with most leading moulding machine brands. We also offer customization to match specific machine requirements.

Absolutely. We specialize in providing tailor-made parts for older or hard-to-find machinery to help extend the lifespan of your equipment.

Standard parts are usually shipped within 2–5 business days. Custom orders may take slightly longer depending on design and availability.